News

Mesh vs Vinyl Banner: Which One Should You Use

Choosing a banner shouldn’t be guesswork. This FlagOh guide breaks the Mesh vs Vinyl Banner decision into three simple parts: Wind and mounting, readability and color, and what it really costs over time. You’ll get a 30-second picker and a safety-first install checklist. We’ll also highlight the quiet tie-breakers—tiny text, true double-sided prints, and glare under stadium lights—so you can choose with confidence.

Which Banner is Right for You?

Start with where the banner lives and how it will be seen—this should drive your decision between the Mesh and Vinyl Banner. Use mesh for windy, open spots—it lets air through and cuts glare. Use vinyl for calm or indoor installs, especially when you need small text, bold solid colors, or true two-sided printing. Do a quick reality check: tape a sample, step back to the real viewing distance, and see if the keywords read in three seconds. If needed, ask your printer for NFPA 701 fire-safety paperwork. Finish smart: choose hems, grommets, and hardware that match how you’ll mount it (fence, wall, or frame).

Best Choice for Your Use Case

Think first about where the banner lives and how people will see it—your environment picks the winner before your artwork does.

- If the site breathes, use mesh. Mesh is ideal for windy environments like fences, scaffolds, and open areas. It allows air to flow through, preventing billowing, and reduces glare when paired with a matte surface. Mesh also works well for stages and outdoor events where sound needs to pass through.

- If the message is tiny or two-sided, use vinyl. Vinyl is perfect for small text, detailed logos, and true double-sided prints. It’s great for high-visibility displays with vibrant colors and intricate graphics. Vinyl also helps mask busy backgrounds and adds privacy, making it suitable for trade shows or event signage.

- Handling & upkeep: Mesh is lightweight, easy to transport, and can withstand outdoor conditions, while vinyl offers a polished, easy-to-clean finish for indoor displays.

- Fast reality checks: Always perform a quick test by checking the readability of your banner from arm’s length and testing it under real lighting conditions.

- Compliance & Standards: If needed, request NFPA 701 fire-safety documentation for the exact substrate and ink set used. Size copy using recognized legibility guidance (letter height vs. viewing distance) and validate with an on-site read test under real lighting

Where to Use & How They Perform

| Factor | Mesh Banner | Vinyl Banner |

| Best for | Windy outdoors, fences, stage scrims | Indoor POP, calm sites, detailed copy |

| Airflow / Wind | ~30–40% openness lowers load | Solid sheet; use rigid frames and extra anchors |

| Readability | Bold graphics, halftones OK; avoid micro text | Best for small text, crisp logos, solid fills |

| DPI at final size | 150–200 | 150–300 |

| Minimum letter height | distance/200 (in) | same |

| Sides | Typically single-sided | True double-sided available |

| Typical lifespan | ~9–24 mo (exposure-dependent) | ~12–36 mo (exposure-dependent) |

| Finishing / Mounting | Grommets 12–24 in; reinforced hems/webbing; mid-span ties; elastic mounts | Grommets 12–24 in; rigid frames/extra anchors; mid-span supports |

| Fire code | NFPA 701 is available on request | NFPA 701 is available on request |

Common mesh SKUs are ~30–40% open area.

What to Use Where — Fast Use-Case Guide

- Construction fence/privacy → Mesh (long runs, lower wind load).

- Stadium/event glare → Mesh + matte (lights, cameras).

- Trade-show POP → Vinyl (sharp small copy, vibrant solids).

- Double-sided needs → Vinyl (true duplex).

If the choice still feels close, let the site conditions break the tie. Prioritize a safer, easier install, then refine color and finish during proofing. This sequence reduces surprises and keeps your rollout on schedule.4

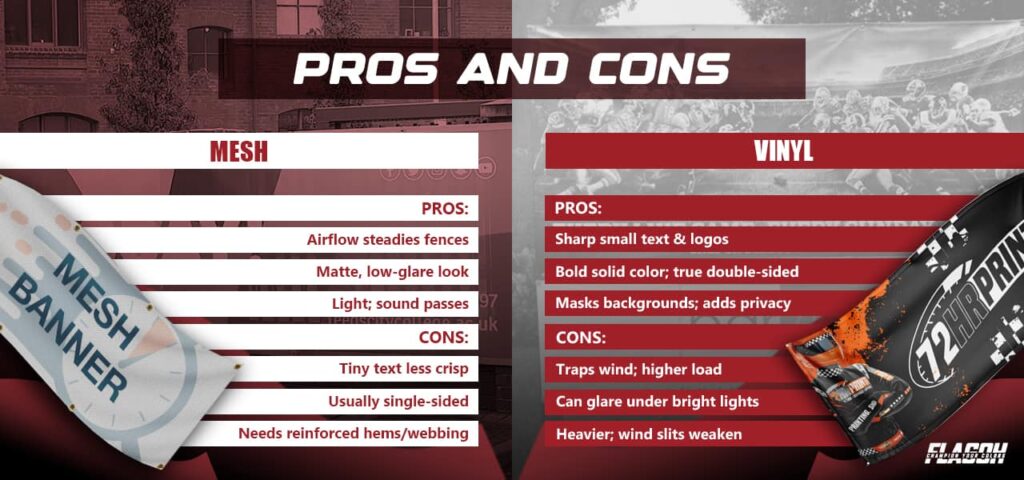

Pros and Cons — Mesh vs Vinyl Banner

This side-by-side view is a shortcut to the real decision: site forces first, message demands second. Scan the pros to see what each material does best, then check the cons to spot the traps—wind load, glare, tiny copy, and privacy needs.

Mesh banner:

- Pros: Vents air on fences and open sites; flexes in gusts; reduces glare with matte surfaces; lighter to handle; lets sound pass near stages and speaker lines.

- Cons: Fine text and tiny logos lose crispness; usually single-sided; edge tears can propagate if hems/webbing aren’t reinforced; works best with elastic mounts.

Vinyl banner:

- Pros: Sharp, small copy and detailed logos; rich, solid color fields; true double-sided options; masks busy backgrounds and adds privacy; easy wipe-clean indoors.

- Cons: Traps wind and loads hardware; more prone to glare under bright lights; heavier on fences; wind slits don’t fix airflow and can weaken the panel.

When you’re unsure, use this quick rule:

Choose mesh when:

- The site is windy, or the banner hangs on fences or open frames.

- You need airflow or sound to pass through.

- Viewers are far away or moving quickly—bold shapes read better.

- Lighting is harsh or on camera; a matte finish helps cut glare.

Choose vinyl when:

- Small text, QR codes, or fine logos must stay sharp.

- You need true double-sided printing.

- The banner mounts to solid walls or rigid frames.

- You want privacy or to hide a busy background.

- Lighting is controlled indoors, and rich, solid color is the goal.

If you’re still on the fence, choose the option that reduces risk at the install, then tune readability with finishing (matte, outlines, reinforced hems). Ask your printer—such as FlagOh—for a quick scale test or swatch under real lighting, confirm fire-safety paperwork, and document your choice so future reprints follow the same winning setup.

Wind, Airflow & Safety

Treat wind as something you route, not fight. Map where gusts come from, how air funnels between structures, the installation height, and the strength of your anchors. Plan a clear load path and safe access.

Mesh for Windy Sites

- Use a mesh with about 30–40% open area.

- Let it flex with elastic connectors.

- Build a strong edge with reinforced hems and webbing.

- Share the load with mid-span ties along long edges.

If You Must Use Vinyl in Wind

- Skip wind slits; they start tears and add little relief.

- Shorten the runs by splitting long panels into modules.

- Increase anchor density or mount to a rigid frame so forces go into the structure, not the sheet.

Design for wind to pass through the setup, not get trapped. For sites expecting 25–35 mph gusts, use porous mesh (≈ one-third open area), hang it on shock cords, and build a load-bearing perimeter with edge tape/webbing and bar-tacks. Distribute forces with intermediate tie points about 1 m apart. Don’t cut slits in vinyl—they start tears and offer little relief. If vinyl is required, split long runs into shorter modules, increase anchor density, and transfer loads into the frame with proper brackets rather than the fabric.

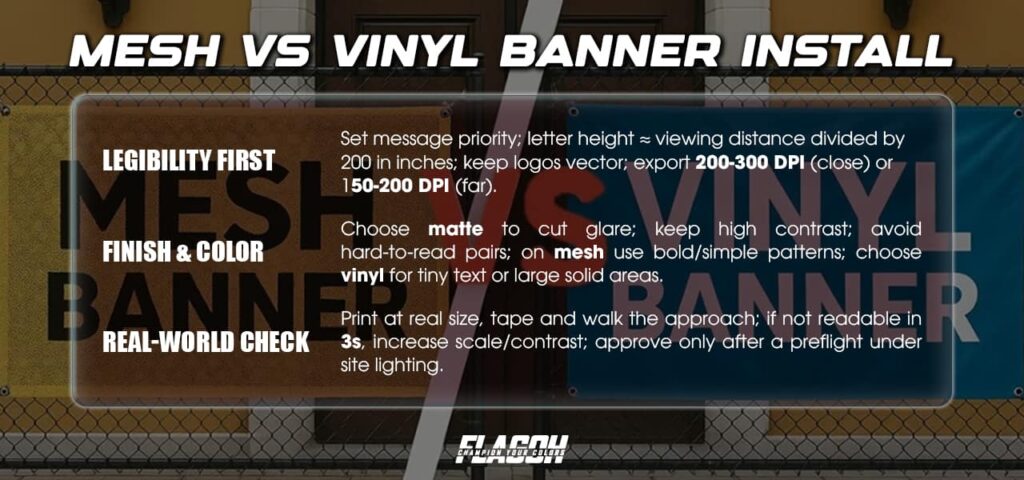

Print Finish, Color & Contrast for Legibility

For Mesh vs Vinyl Banner prints, treat legibility as a chain—viewing distance, motion, message priority, and lighting. Set the message hierarchy first, then choose type weight and spacing.

Banner Resolution and Minimum Letter Size

- Close viewing → export higher resolution; far viewing → moderate resolution prints faster.

- Minimum letter size: viewing distance ÷ 200 (inches).

- Logos: keep in vector for crisp edges.

- Mesh: use bold halftones; avoid tiny dot patterns that disappear through holes.

- Print a real-size crop of key areas before approval to check edges and fine detail.

Best DPI Settings for Banner Printing

- Close viewing: 200–300 DPI.

- Distant viewing: 150–200 DPI.

- For photos, use high-quality PNG/TIFF with minimal compression.

- Review a mockup under real lighting; adjust contrast as needed.

Banner Finish, Color & Contrast

- Matte finish cuts glare under stadium lights and bright sun; gloss can make solid colors look richer indoors.

- Keep contrast high and avoid hard-to-read pairs for small copy (e.g., red on black or yellow on white).

- On mesh, keep patterns large and simple so fine textures aren’t lost. For very small text or large solid color areas, vinyl is usually the safer choice.

- Do a quick field test—tape a printout at size, walk the approach path, and film it on your phone.

- If keywords aren’t readable in three seconds, increase scale or contrast, then run a final preflight—the FlagOh standard—before approving the proof.

Do a quick field test—tape a printout at full size, walk the actual approach path, and record it on your phone. If the key words aren’t readable within three seconds, increase scale or contrast, then run a final preflight check before approving the proof.

How to Install Mesh vs Vinyl Banner

For Mesh vs Vinyl Banner installs, don’t fight the wind—let it move through the setup. Choose solid anchor points, reinforce the edges, and use elastic connectors so the banner can flex and spread the load instead of putting all the stress on one spot.

Prep & Measure

- Map the load path (where wind hits/escapes) and pick solid anchor points.

- Check clearances (doors, vehicles, exits, sightlines) and remove sharp burrs.

- Do a quick mock hang to confirm orientation and panel IDs.

- Create a simple job card (site photos, FR/permit docs, contacts, take-down threshold).

Hardware & Finishing

- Specify welded hems with internal webbing; add corner gussets.

- Use elastic connectors (bungees/shock cord); avoid brittle zip-ties.

- Prefer stainless hardware; pad contact points (hose sleeves/edge guards).

- Keep fasteners consistent so the banner flexes evenly.

Mounting Steps

- Hang the top edge first, then lock corners.

- Add mid-span supports along long edges to share the load.

- Tension gradually in a criss-cross pattern: smooth face, still able to breathe.

- Do a safety pass, then take documentation photos; fix any flutter with extra supports.

End with a quick safety loop: scan for scallops or edge flutter, re-tension where needed, and document anchors with a few photos. Keep a small field kit—FlagOh suggests elastic ties, repair tape, and spare clips—and set a simple post-storm check; these habits prevent surprises and keep the banner looking clean for its full run.

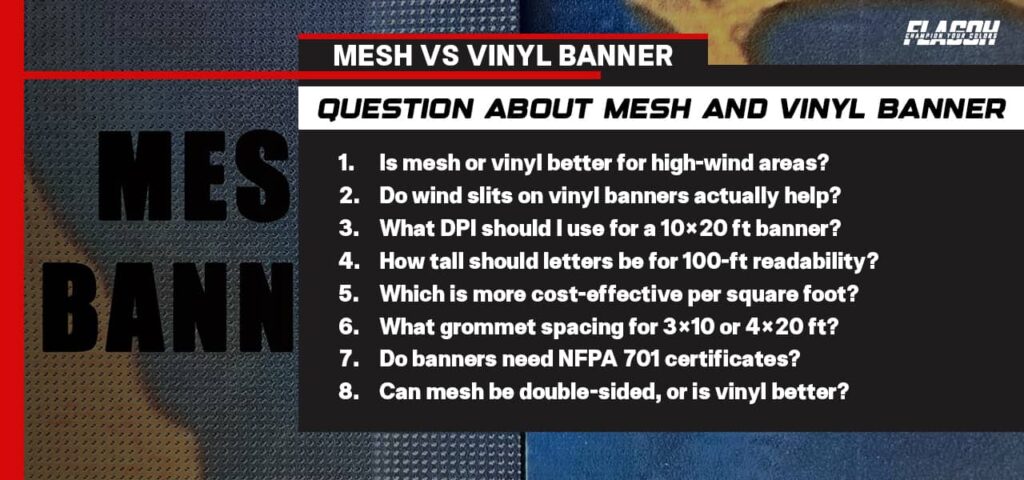

Questions About Mesh and Vinyl Banner

Use this Mini-FAQ to clear the most common blockers fast in your Mesh vs Vinyl Banner decision—wind choice, image sharpness, viewing distance, service life, hardware spacing, and fire-safety rules.

Is mesh or vinyl better for high-wind areas?

Mesh. It’s 30–40% openness vents air; pair with elastic mounts and mid-span support.

Do wind slits on vinyl banners actually help?

No. They create stress risers that weaken the panel. Use mesh + proper finishing instead.

What DPI should I use for a 10×20 ft banner?

Export at 150–300 DPI at full size. Higher rarely improves viewing, but balloons file weight.

How tall should letters be for 100-ft readability?

Use distance/200 → about 6 in tall at 100 ft.

Which is more cost-effective per square foot?

For low-wind indoor use, vinyl often wins. For wind-exposed sites, mesh can reduce failures and total cost.

What grommet spacing for 3×10 or 4×20 ft?

Plan 12–24 in around the perimeter; add mid-span ties on long edges.

Do banners need NFPA 701 certificates?

Often, yes—many venues and municipalities require NFPA 701 or equivalent FR documentation.

Can mesh be double-sided, or is vinyl better?

True double-sided is a vinyl strength; most mesh is printed single-sided.

Choose mesh for windy sites and use elastic mounts. Avoid wind slits. Choose vinyl for very small text or true double-sided prints. Export at 150-300 DPI, size letters by distance divided by 200 inches, and plan grommets every 12-24 inches. Check NFPA 701 if the venue requires it. If you are unsure, tape a full-size sample on-site and let the conditions guide the choice.

Choosing the right banner material comes down to matching it to your specific environment and design needs. Whether you’re dealing with wind, lightning, or the need for crisp, small text, each option offers unique benefits and trade-offs. Consider factors like placement, visibility, and exposure before making your decision. And if you’re ever unsure about the Mesh vs Vinyl Banner fit for your site, FlagOh is here to guide you, ensuring you get a durable, effective, and perfect banner for your project.

Arizona Cardinals Flag

Arizona Cardinals Flag Atlanta Falcons Flag

Atlanta Falcons Flag Baltimore Ravens Flag

Baltimore Ravens Flag Buffalo Bills Flag

Buffalo Bills Flag Carolina Panthers Flag

Carolina Panthers Flag Chicago Bears Flag

Chicago Bears Flag Cincinnati Bengals Flag

Cincinnati Bengals Flag Cleveland Browns Flag

Cleveland Browns Flag Dallas Cowboys Flag

Dallas Cowboys Flag Denver Broncos Flag

Denver Broncos Flag Detroit Lions Flag

Detroit Lions Flag Green Bay Packers Flag

Green Bay Packers Flag Houston Texans Flag

Houston Texans Flag Indianapolis Colts Flag

Indianapolis Colts Flag Jacksonville Jaguars Flag

Jacksonville Jaguars Flag Kansas City Chiefs Flag

Kansas City Chiefs Flag Las Vegas Raiders Flag

Las Vegas Raiders Flag Los Angeles Chargers Flag

Los Angeles Chargers Flag Los Angeles Rams Flag

Los Angeles Rams Flag Miami Dolphins Flag

Miami Dolphins Flag Minnesota Vikings Flag

Minnesota Vikings Flag New England Patriots Flag

New England Patriots Flag New Orleans Saints Flag

New Orleans Saints Flag New York Giants Flag

New York Giants Flag New York Jets Flag

New York Jets Flag Philadelphia Eagles Flag

Philadelphia Eagles Flag Pittsburgh Steelers Flag

Pittsburgh Steelers Flag San Francisco 49ers Flag

San Francisco 49ers Flag Seattle Seahawks Flag

Seattle Seahawks Flag Tampa Bay Buccaneers Flag

Tampa Bay Buccaneers Flag Tennessee Titans Flag

Tennessee Titans Flag Washington Commanders Flag

Washington Commanders Flag Arizona Diamondbacks Flag

Arizona Diamondbacks Flag Atlanta Braves Flag

Atlanta Braves Flag Baltimore Orioles Flag

Baltimore Orioles Flag Boston Red Sox Flag

Boston Red Sox Flag Chicago Cubs Flag

Chicago Cubs Flag Chicago White Sox Flag

Chicago White Sox Flag Cincinnati Reds Flag

Cincinnati Reds Flag Cleveland Guardians Flag

Cleveland Guardians Flag Colorado Rockies Flag

Colorado Rockies Flag Detroit Tigers Flag

Detroit Tigers Flag Houston Astros Flag

Houston Astros Flag Kansas City Royals Flag

Kansas City Royals Flag Los Angeles Angels Flag

Los Angeles Angels Flag Los Angeles Dodgers Flag

Los Angeles Dodgers Flag Miami Marlins Flag

Miami Marlins Flag Milwaukee Brewers Flag

Milwaukee Brewers Flag Minnesota Twins Flag

Minnesota Twins Flag New York Mets Flag

New York Mets Flag New York Yankees Flag

New York Yankees Flag Oakland Athletics Flag

Oakland Athletics Flag Philadelphia Phillies Flag

Philadelphia Phillies Flag Pittsburgh Pirates Flag

Pittsburgh Pirates Flag San Diego Padres Flag

San Diego Padres Flag San Francisco Giants Flag

San Francisco Giants Flag Seattle Mariners Flag

Seattle Mariners Flag St. Louis Cardinals Flag

St. Louis Cardinals Flag Tampa Bay Rays Flag

Tampa Bay Rays Flag Texas Rangers Flag

Texas Rangers Flag Toronto Blue Jays Flag

Toronto Blue Jays Flag Washington Nationals Flag

Washington Nationals Flag Atlanta Hawks Flag

Atlanta Hawks Flag Boston Celtics Flag

Boston Celtics Flag Brooklyn Nets Flag

Brooklyn Nets Flag Charlotte Hornets Flag

Charlotte Hornets Flag Chicago Bulls Flag

Chicago Bulls Flag Cleveland Cavaliers Flag

Cleveland Cavaliers Flag Dallas Mavericks Flag

Dallas Mavericks Flag Denver Nuggets Flag

Denver Nuggets Flag Detroit Pistons Flag

Detroit Pistons Flag Golden State Warriors Flag

Golden State Warriors Flag Houston Rockets Flag

Houston Rockets Flag Indiana Pacers Flag

Indiana Pacers Flag LA Clippers Flag

LA Clippers Flag Los Angeles Lakers Flag

Los Angeles Lakers Flag Memphis Grizzlies Flag

Memphis Grizzlies Flag Miami Heat Flag

Miami Heat Flag Milwaukee Bucks Flag

Milwaukee Bucks Flag Minnesota Timberwolves Flag

Minnesota Timberwolves Flag New Orleans Pelicans Flag

New Orleans Pelicans Flag New York Knicks Flag

New York Knicks Flag Oklahoma City Thunder Flag

Oklahoma City Thunder Flag Orlando Magic Flag

Orlando Magic Flag Philadelphia 76ers Flag

Philadelphia 76ers Flag Phoenix Suns Flag

Phoenix Suns Flag Portland Trail Blazers Flag

Portland Trail Blazers Flag Sacramento Kings Flag

Sacramento Kings Flag San Antonio Spurs Flag

San Antonio Spurs Flag Toronto Raptors Flag

Toronto Raptors Flag Utah Jazz Flag

Utah Jazz Flag Washington Wizards Flag

Washington Wizards Flag Anaheim Ducks Flag

Anaheim Ducks Flag Arizona Coyotes Flag

Arizona Coyotes Flag Boston Bruins Flag

Boston Bruins Flag Buffalo Sabres Flag

Buffalo Sabres Flag Calgary Flames Flag

Calgary Flames Flag Carolina Hurricanes Flag

Carolina Hurricanes Flag Chicago Blackhawks Flag

Chicago Blackhawks Flag Colorado Avalanche Flag

Colorado Avalanche Flag Columbus Blue Jackets Flag

Columbus Blue Jackets Flag Dallas Stars Flag

Dallas Stars Flag Detroit Red Wings Flag

Detroit Red Wings Flag Edmonton Oilers Flag

Edmonton Oilers Flag Florida Panthers Flag

Florida Panthers Flag Los Angeles Kings Flag

Los Angeles Kings Flag Minnesota Wild Flag

Minnesota Wild Flag Montreal Canadiens Flag

Montreal Canadiens Flag Nashville Predators Flag

Nashville Predators Flag New Jersey Devils Flag

New Jersey Devils Flag New York Islanders Flag

New York Islanders Flag New York Rangers Flag

New York Rangers Flag Ottawa Senators Flag

Ottawa Senators Flag Philadelphia Flyers Flag

Philadelphia Flyers Flag Pittsburgh Penguins Flag

Pittsburgh Penguins Flag San Jose Sharks Flag

San Jose Sharks Flag Seattle Kraken Flag

Seattle Kraken Flag St. Louis Blues Flag

St. Louis Blues Flag Tampa Bay Lightning Flag

Tampa Bay Lightning Flag Toronto Maple Leafs Flag

Toronto Maple Leafs Flag Vancouver Canucks Flag

Vancouver Canucks Flag Vegas Golden Knights Flag

Vegas Golden Knights Flag Washington Capitals Flag

Washington Capitals Flag Winnipeg Jets Flag

Winnipeg Jets Flag