News

Nylon vs Polyester flag: Indoor vs Outdoor Use | FlagOh

Choosing a Nylon vs Polyester flag isn’t about a universal “best”—it’s about your wind, look, and print method. This guide turns specs (denier/ply, dye-sub vs screen/appliqué, single-reverse vs double-sided) into clear choices, so you can match fabric to conditions and get the longest life per dollar.

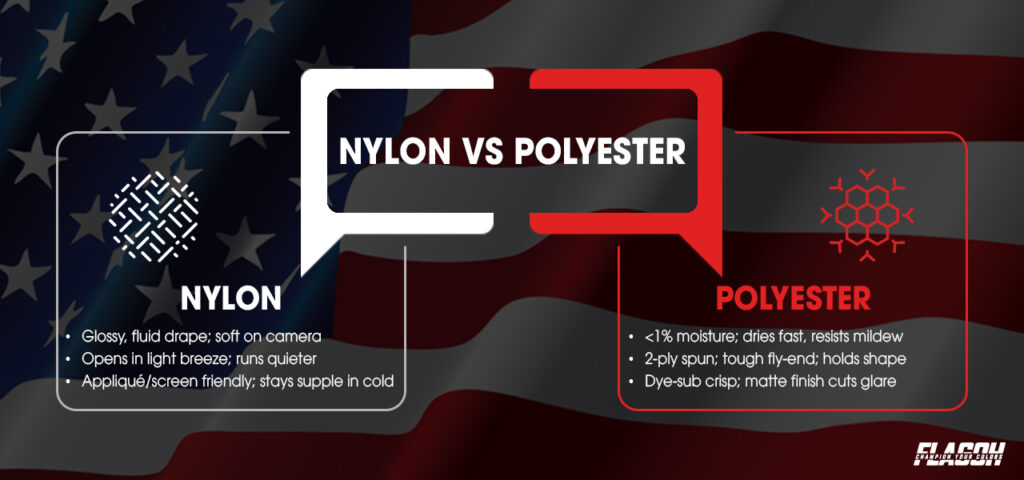

Pros and cons of Nylon vs Polyester flag

There’s no universal winner in Nylon vs Polyester flag—only the right match for your site. Use these field cues—image quality, tall-pole steadiness, and fly-end wear—plus wind, print, and maintenance factors to dial in the spec that delivers the look and lifespan you need.

Nylon flag

Pros:

- Gloss and fluid drape → ideal for indoor displays and light wind; looks premium on camera with soft folds.

- Light hoist, opens in low breeze; quieter on balconies and in dense neighborhoods.

- Pairs well with appliqué/screen for bold crests and a heritage sewn look; stays supple in cold weather.

Cons:

- Moisture regain ≈3–4% → gets heavier when wet and dries slower than polyester.

- In 20–40 mph winds, the fly end frays faster than 2-ply spun polyester; it needs heat-sealed edges and adequate stitch density.

- Higher elasticity can, over time, lengthen the fly end and encourage stitch creep if lockstitch density is low.

- High sheen can create specular hotspots under LED/studio lighting if not managed.

Polyester flag

Pros:

- Moisture regain <1% → dries fast, lower mildew risk; salt/dust rinse off more easily.

- 2-ply spun polyester is tough at the fly end and holds up in 15–40+ mph; dimensionally stable, so logos stay truer on tall poles or vehicle mounts.

- Dye-sublimation yields crisp edges/gradients; matte surface reduces glare on camera.

- Solution-dyed options resist fade better in high-UV regions; hot-knife/ultrasonic edges are usually very clean.

Cons:

- Heavier → needs a bit more wind to open; can be louder in sharp gusts.

- Can feel stiffer in cold, and look “heavier” on small poles.

Printing & two-sided readability

- Dye-sublimation requires ≥65% polyester (ideally 100%); sharpest with transfer and a 1:1 proof for micro-type.

- Nylon suits screen/appliqué for large, bold marks and visible stitch channels.

- Single-reverse: lighter, cheaper, ~80–100% show-through—less wind load/hardware strain.

- Double-sided: two printed layers with a blackout liner, true two-way reading, but heavier—use only when essential.

Real-world performance nuances

Elasticity & seam stress:

- Nylon stretches more (≈18–30% at break): cushions gust shocks but can lengthen the fly end (trailing edge) and loosen halyard tension over time if lockstitch density is low.

- Polyester stretches less (≈12–20%): keeps panels flatter and artwork truer; bar-tacks and corner patches take load more predictably.

Cold, heat & moisture interplay:

- Cold: Nylon stays supple, so small flags open in lighter air; polyester may feel stiffer and need more breeze.

- Wet cycles: Nylon tightens its hand briefly after rain, raising flutter fatigue at the fly end until dry; polyester sheds water faster, returning mass/fatigue to baseline sooner.

Edge heat-sealing & fray control: Both are thermoplastics, but polyester typically takes a cleaner bead with hot-knife/ultrasonic cutting; nylon also benefits, yet its moisture uptake can leave a slightly fuzzier micro-edge if sealing is inconsistent. If no heat sealing, insist on more stitch rows and an early-trim routine.

Noise & neighbor-friendliness: Heavier, low-porosity builds (e.g., 2-ply poly) can snap audibly in gusts. For balconies/quiet streets, choose light nylon or single-reverse poly to cut noise without sacrificing image.

Salt, dust & soil: Polyester’s lower hydrophilicity means salt/dirt releases more easily in a cool rinse. Nylon can show faint salt tide lines after repeated marine mist cycles—quick rinses keep colors crisp.

Let conditions lead the choice: nylon for lively motion and refined look in light air; 2-ply spun polyester for uptime in gusts, salt, or high UV. The rest is built and care—edge sealing, strong headers, proper stitch density, and seasonal rotation. See Hardware & finishing that extend life for the exact spec.

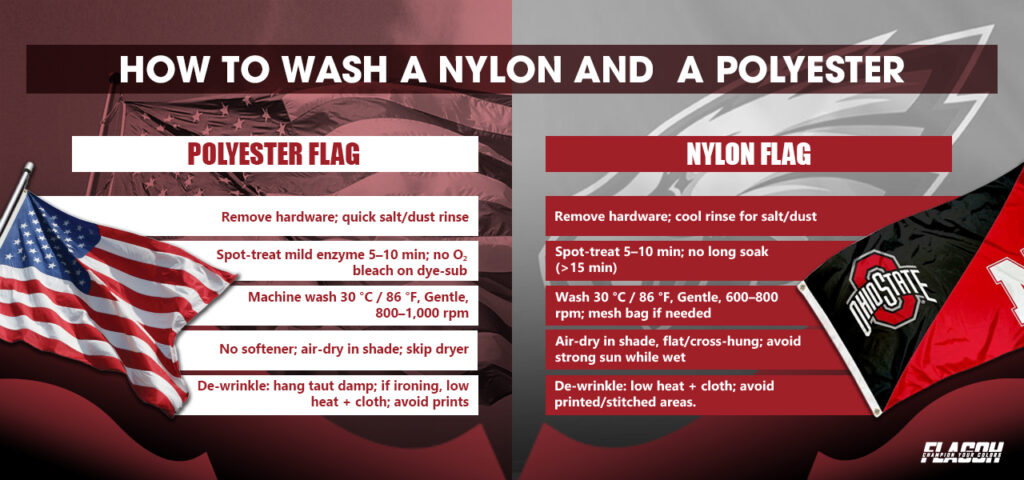

How to wash a Polyester flag and a Nylon flag

If you’re searching for how to wash a Polyester flag and a Nylon flag, remember that care isn’t one-size-fits-all. Polyester and nylon react differently to water, heat, and detergents—the wrong settings can dull dye-sub prints, stress seams, and shorten fly-end life. This guide gives precise temperatures, cycles, spin ranges, and air-dry steps so both fabrics keep their color, shape, and readability—especially with dye-sublimation or appliqué graphics.

Step-by-step — Polyester

- Remove hardware, quick rinse to clear salt/dust.

- Pre-treat spots: mild enzyme 5–10 min; avoid oxygen bleach on dye-sub prints (can dull color). Consider only plain white, non-printed poly.

- Machine wash 30 °C / 86 °F, Gentle, 800–1,000 rpm.

- No fabric softener (reduces fiber strength and makes the surface “waxy”).

- Air-dry in shade; poly dries fast—still skip the dryer to protect adhesive layers/prints.

- De-wrinkle: Hang taut while slightly damp; if pressing, use low heat, pressing cloth, never touch the dye-sub area directly.

Step-by-step — Nylon

- Remove hardware (halyard clips, carabiners). Check grommets for burrs.

- Quick rinse in cool water if exposed to salt/dust (reduces tide lines).

- Pre-treat spots: A few drops of mild detergent or enzyme cleaner for 5–10 min.

- Don’t long-soak (>15 min) to limit water uptake.

- Machine wash at 30 °C / 86 °F, Gentle, 600–800 rpm; use a mesh laundry bag if your agitator is aggressive.

- Optional extra rinse if your tap water is hard/alkaline.

- Air-dry in shade, laid flat or cross-hung so water drains evenly. Avoid strong sun while wet to limit temporary hand tightening.

- De-wrinkle: If needed, press on low heat with a pressing cloth; avoid direct contact with printed/stitched graphics.

Salt/marine care:

- After each sea spray/salt-air day: cool-water rinse 1–2 min per side.

- Nylon: especially helpful—reduces salt tide lines and fly-end fatigue after wet cycles.

- Polyester: sheds salt more easily, but rinsing still preserves color, freshness, and print integrity.

Stain & odor playbook:

- Dust/soil: cool-water spray + soft brush with the grain → wash as above.

- Oils/grease: dab a tiny amount of mild dish soap, blot—don’t scrub hard—then wash.

- Bird droppings/tree sap: soften with warm (not hot) water + enzyme 5–10 min, lift gently with a plastic card, wash.

- Musty odor: short 10-min soak at 30 °C / 86 °F with a little white vinegar (≈ 1–2 tbsp / 5 L), then rinse well; no chlorine bleach.

Treat cleaning as part of your lifespan plan: rinse promptly after salt exposure, schedule gentle washes based on days flown, and rotate a spare to reduce fatigue at a single mount point. After each wash, check the fly end and header, trim any loose threads, and store only when fully dry. Keep a simple care log (date, conditions, notes) so you can spot patterns early and adjust rotation or reinforcement before wear becomes visible.

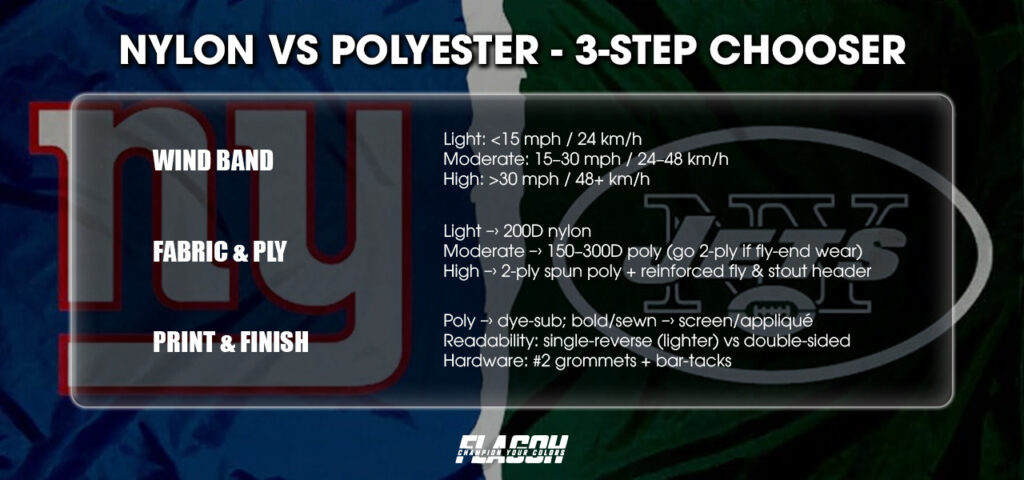

How to choose Nylon vs Polyester flag

Use this three-step chooser to translate your conditions into a confident Nylon vs Polyester flag pick. First, gauge your site’s wind profile (not just peak gusts but typical hours per day). Then align that band with denier/ply for durability, and finally lock in printing/finishing so the artwork reads cleanly without overstressing seams or hardware.

Step 1 — Identify your wind band

- Light: <15 mph (24 km/h) — tree-sheltered yards, low-rise neighborhoods.

- Moderate: 15–30 mph (24–48 km/h) — open lots, inshore coastal, hilltops.

- High: >30 mph (48+ km/h) — headlands, ridgelines, exposed stadium sites.

Step 2 — Match fabric & denier to that band

- <15 mph: 200D nylon for motion and sheen.

- 15–30 mph: 150–300D polyester; if fly-end wear shows up, move to 2-ply spun polyester.

- >30 mph: 2-ply spun polyester with a reinforced fly end and stout header.

Step 3 — Choose print method & finishing

- Printing: Pick dye-sub for polyester; use screen/appliqué when you want bold, sewn texture. See Printing & two-sided readability.

- Readability: Choose single-reverse for lower weight; pick double-sided only when two-way reading is essential. See Printing & two-sided readability.

- Finishing: Use standard #2 grommets and reinforce stress points with bar-tacks. See Hardware & finishing that extend life for minimum specs.

Once you’ve mapped your choice, sanity-check it against real use: frequent gusts, vehicle mounting, or salt exposure justify stronger ply and added reinforcement, while indoor/studio display favors lighter nylon for drape and sheen. If your conditions change seasonally, adjust fabric/ply or overall flag size, confirm hardware capacity, and proceed to the specs section for fine-tuning.

Materials, specs & printing

We anchor durability and colorfastness with common methods: AATCC TM16 (xenon-arc lightfastness), ISO 105-B02 (color fastness to artificial light), ASTM D2261 (tongue tear), ASTM D5034 (grab tensile), và NFPA 701 (flame resistance for indoor banners).

Denier & ply explained

- Denier = yarn thickness; 150D / 200D / 300D are common for flags.

- Ply: 2-ply spun polyester (two-layer, spun yarns) boosts real-world tongue-tear resistance at the fly end (see ASTM D2261), with solid tensile baselines (ASTM D5034).

UV & fade resistance

- Xenon-arc exposure simulates sunlight. Dark reds/blacks fade fastest.

- Polyester with dye-sub inks often looks fresher longer in strong-sun regions (AZ/FL/TX). Rotate/replace based on visual thresholds.

Print compatibility & color quality

- On polyester, dye-sub gives crisp edges and smooth gradients; for bold marks or a heritage sewn look (including nylon), use screen or appliqué.

- Choose single-reverse to minimize weight and wind load; use double-sided only when two-way reading is essential

Use specs to match intent (durability, art complexity, readability). Then align hardware and size in Build, sizing & longevity. These ranges reflect EU/US/CA field observations documented by FlagOh.

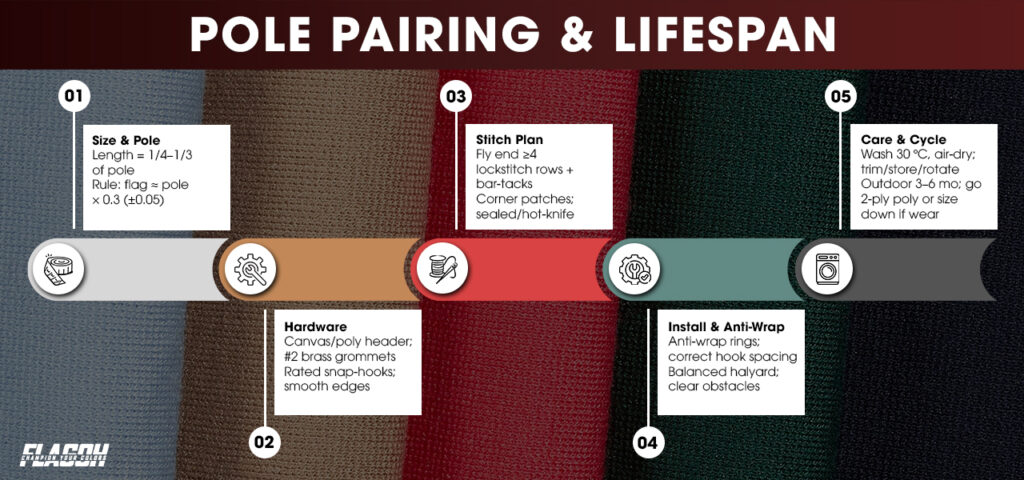

Nylon vs Polyester flag sizing and making it last

Now that you’ve selected a Nylon vs Polyester flag, lock in the build so it survives real-world stress. Hardware, stitch plan, and pole pairing often determine lifespan more than fabric alone. Follow the minimum hardware and stitch reinforcements in Hardware & finishing that extend life, canvas/poly header, a fly end with 4+ lockstitch rows and bar-tacks, plus a flag size that matches ¼–⅓ of pole height. When uncertain, choose a smaller flag or step reinforcement up.

Hardware & finishing that extend life

- #2 brass grommets ≈ 3/8 in (≈ 9.5 mm) ID with canvas/poly header tape.

- Fly end: ≥ 4 rows lockstitch, bar-tacks at stress points, corner patches for gusty installs.

- Anti-wrap rings and correct snap-hook spacing reduce tangles and seam strain.

The specs below are minimum baselines; always check your pole/hardware ratings before upsizing.

Size & pole pairing:

Rule of thumb: flag length ≈ one-quarter to one-third of pole height (0.25–0.33×).

| Pole | Wall-mount 5–6 ft (1.5–1.8 m) | Yard 15 ft (4.6 m) | Yard 20 ft (6.1 m) | Yard 25 ft (7.6 m) | Yard 30 ft (9.1 m) |

| Recommended flag | 2×3 or 2.5×4 ft | 3×5 ft | 3×5 ft | 4×6 ft | 5×8 ft |

Lifespan, care & cost/day:

- Daily outdoor: replace about 3–6 months (depends on wind/UV/salt); indoor: 12–36 months with care.

- Care: follow the Wash Guide above for temperature, cycle, and drying.

- Best practice: trim loose threads early; store dry & shaded; rotate flags to balance wear.

- Cost/day: price ÷ expected months → compare 200D nylon vs 2-ply polyester within your wind band.

Do a quick field check after installation: glide your hand along the fly end for loose threads, confirm grommet edges aren’t sharp, and watch for wraps in gusts. If wrapping persists or flapping is loud, add anti-wrap rings, adjust snap-hook spacing, or size down. Track replacements to calculate cost/day; if it’s creeping up, move to 2-ply spun polyester, reduce exposure hours, or switch to single-reverse (lighter) rather than double-sided (heavier) unless two-sided readability is essential.

What You Need to Know

Have specific questions about your Nylon vs Polyester flag? This Mini-FAQ answers the top PAA queries—wind-band lifespan, 20–30 mph denier, dye-sub, single-reverse vs double-sided, pole sizing, UV fade, moisture, noise, NFPA 701, and cost/day.

Is nylon or polyester better for flags?

Neither is universally better: nylon for light-air motion and a glossy look; 2-ply polyester for tougher wind/UV/salt conditions.

Which lasts longer outdoors, nylon or polyester?

In 15–40+ mph winds, 2-ply spun polyester typically outlasts nylon thanks to better fly-end abrasion resistance.

Can I dye-sublimate on nylon?

Use polyester for dye-sub; for nylon, use screen printing or appliqué (see Printing)

Single-reverse vs double-sided—what’s the difference?

Single-reverse shows through the back at roughly 80–100%; double-sided uses two printed layers with a blackout liner for true two-sided readability and higher weight.

What size flag for a 20 ft pole?

3×5 ft is standard; 4×6 ft gives a bolder look if local wind allows.

Which fades slower in high-UV?

Polyester with dye-sub inks often appears fresher longer in strong sun (per AATCC TM16 / ISO 105-B02 exposure principles).

Does nylon absorb more water than polyester?

Yes—nylon absorbs more and dries more slowly than polyester (see Pros & Cons).

Which fabric is quieter in neighborhood winds?

Nylon is generally lighter and quieter; heavier 2-ply polyester can flap louder in gusts.

Do indoor banners need NFPA 701?

Many venues require NFPA 701 flame resistance for indoor hanging. Check local codes or facility policies. In the showdown of Nylon vs Polyester flag, the winner is determined by your home field advantage. For a fluid, elegant drape and brilliant motion in light breezes, nylon is the premier choice. For a rugged workhorse that stands up to strong winds, salt air, and harsh UV rays, 2-ply polyester is the undisputed champion. The experts at FlagOh are here to help you translate your real-world conditions into the perfect flag choice, ensuring every unfurling is a worthwhile investment.

Arizona Cardinals Flag

Arizona Cardinals Flag Atlanta Falcons Flag

Atlanta Falcons Flag Baltimore Ravens Flag

Baltimore Ravens Flag Buffalo Bills Flag

Buffalo Bills Flag Carolina Panthers Flag

Carolina Panthers Flag Chicago Bears Flag

Chicago Bears Flag Cincinnati Bengals Flag

Cincinnati Bengals Flag Cleveland Browns Flag

Cleveland Browns Flag Dallas Cowboys Flag

Dallas Cowboys Flag Denver Broncos Flag

Denver Broncos Flag Detroit Lions Flag

Detroit Lions Flag Green Bay Packers Flag

Green Bay Packers Flag Houston Texans Flag

Houston Texans Flag Indianapolis Colts Flag

Indianapolis Colts Flag Jacksonville Jaguars Flag

Jacksonville Jaguars Flag Kansas City Chiefs Flag

Kansas City Chiefs Flag Las Vegas Raiders Flag

Las Vegas Raiders Flag Los Angeles Chargers Flag

Los Angeles Chargers Flag Los Angeles Rams Flag

Los Angeles Rams Flag Miami Dolphins Flag

Miami Dolphins Flag Minnesota Vikings Flag

Minnesota Vikings Flag New England Patriots Flag

New England Patriots Flag New Orleans Saints Flag

New Orleans Saints Flag New York Giants Flag

New York Giants Flag New York Jets Flag

New York Jets Flag Philadelphia Eagles Flag

Philadelphia Eagles Flag Pittsburgh Steelers Flag

Pittsburgh Steelers Flag San Francisco 49ers Flag

San Francisco 49ers Flag Seattle Seahawks Flag

Seattle Seahawks Flag Tampa Bay Buccaneers Flag

Tampa Bay Buccaneers Flag Tennessee Titans Flag

Tennessee Titans Flag Washington Commanders Flag

Washington Commanders Flag Arizona Diamondbacks Flag

Arizona Diamondbacks Flag Atlanta Braves Flag

Atlanta Braves Flag Baltimore Orioles Flag

Baltimore Orioles Flag Boston Red Sox Flag

Boston Red Sox Flag Chicago Cubs Flag

Chicago Cubs Flag Chicago White Sox Flag

Chicago White Sox Flag Cincinnati Reds Flag

Cincinnati Reds Flag Cleveland Guardians Flag

Cleveland Guardians Flag Colorado Rockies Flag

Colorado Rockies Flag Detroit Tigers Flag

Detroit Tigers Flag Houston Astros Flag

Houston Astros Flag Kansas City Royals Flag

Kansas City Royals Flag Los Angeles Angels Flag

Los Angeles Angels Flag Los Angeles Dodgers Flag

Los Angeles Dodgers Flag Miami Marlins Flag

Miami Marlins Flag Milwaukee Brewers Flag

Milwaukee Brewers Flag Minnesota Twins Flag

Minnesota Twins Flag New York Mets Flag

New York Mets Flag New York Yankees Flag

New York Yankees Flag Oakland Athletics Flag

Oakland Athletics Flag Philadelphia Phillies Flag

Philadelphia Phillies Flag Pittsburgh Pirates Flag

Pittsburgh Pirates Flag San Diego Padres Flag

San Diego Padres Flag San Francisco Giants Flag

San Francisco Giants Flag Seattle Mariners Flag

Seattle Mariners Flag St. Louis Cardinals Flag

St. Louis Cardinals Flag Tampa Bay Rays Flag

Tampa Bay Rays Flag Texas Rangers Flag

Texas Rangers Flag Toronto Blue Jays Flag

Toronto Blue Jays Flag Washington Nationals Flag

Washington Nationals Flag Atlanta Hawks Flag

Atlanta Hawks Flag Boston Celtics Flag

Boston Celtics Flag Brooklyn Nets Flag

Brooklyn Nets Flag Charlotte Hornets Flag

Charlotte Hornets Flag Chicago Bulls Flag

Chicago Bulls Flag Cleveland Cavaliers Flag

Cleveland Cavaliers Flag Dallas Mavericks Flag

Dallas Mavericks Flag Denver Nuggets Flag

Denver Nuggets Flag Detroit Pistons Flag

Detroit Pistons Flag Golden State Warriors Flag

Golden State Warriors Flag Houston Rockets Flag

Houston Rockets Flag Indiana Pacers Flag

Indiana Pacers Flag LA Clippers Flag

LA Clippers Flag Los Angeles Lakers Flag

Los Angeles Lakers Flag Memphis Grizzlies Flag

Memphis Grizzlies Flag Miami Heat Flag

Miami Heat Flag Milwaukee Bucks Flag

Milwaukee Bucks Flag Minnesota Timberwolves Flag

Minnesota Timberwolves Flag New Orleans Pelicans Flag

New Orleans Pelicans Flag New York Knicks Flag

New York Knicks Flag Oklahoma City Thunder Flag

Oklahoma City Thunder Flag Orlando Magic Flag

Orlando Magic Flag Philadelphia 76ers Flag

Philadelphia 76ers Flag Phoenix Suns Flag

Phoenix Suns Flag Portland Trail Blazers Flag

Portland Trail Blazers Flag Sacramento Kings Flag

Sacramento Kings Flag San Antonio Spurs Flag

San Antonio Spurs Flag Toronto Raptors Flag

Toronto Raptors Flag Utah Jazz Flag

Utah Jazz Flag Washington Wizards Flag

Washington Wizards Flag Anaheim Ducks Flag

Anaheim Ducks Flag Arizona Coyotes Flag

Arizona Coyotes Flag Boston Bruins Flag

Boston Bruins Flag Buffalo Sabres Flag

Buffalo Sabres Flag Calgary Flames Flag

Calgary Flames Flag Carolina Hurricanes Flag

Carolina Hurricanes Flag Chicago Blackhawks Flag

Chicago Blackhawks Flag Colorado Avalanche Flag

Colorado Avalanche Flag Columbus Blue Jackets Flag

Columbus Blue Jackets Flag Dallas Stars Flag

Dallas Stars Flag Detroit Red Wings Flag

Detroit Red Wings Flag Edmonton Oilers Flag

Edmonton Oilers Flag Florida Panthers Flag

Florida Panthers Flag Los Angeles Kings Flag

Los Angeles Kings Flag Minnesota Wild Flag

Minnesota Wild Flag Montreal Canadiens Flag

Montreal Canadiens Flag Nashville Predators Flag

Nashville Predators Flag New Jersey Devils Flag

New Jersey Devils Flag New York Islanders Flag

New York Islanders Flag New York Rangers Flag

New York Rangers Flag Ottawa Senators Flag

Ottawa Senators Flag Philadelphia Flyers Flag

Philadelphia Flyers Flag Pittsburgh Penguins Flag

Pittsburgh Penguins Flag San Jose Sharks Flag

San Jose Sharks Flag Seattle Kraken Flag

Seattle Kraken Flag St. Louis Blues Flag

St. Louis Blues Flag Tampa Bay Lightning Flag

Tampa Bay Lightning Flag Toronto Maple Leafs Flag

Toronto Maple Leafs Flag Vancouver Canucks Flag

Vancouver Canucks Flag Vegas Golden Knights Flag

Vegas Golden Knights Flag Washington Capitals Flag

Washington Capitals Flag Winnipeg Jets Flag

Winnipeg Jets Flag